Your project kickoff is going gangbusters. You have planned, plotted, and researched all of the variables and potential scenarios. You have spent days at the job site, doing due diligence, collecting your environmental lab samples, documenting, assembling, and dropping them off at your favorite lab. The last thing you need is your timeline getting derailed or additional expenses because of an oversight with your samples, sampling plan, paperwork, or procedure.

Scientists are sticklers for detail, yes, but laboratory personnel are not trying to make your life difficult when they ask you to resample. It is a requirement of their certification to follow strict “Sample Acceptance Criteria” when receiving samples for analysis. The sample condition, container, preservation, temperature, and holding time all play a role in whether or not the sample can be accepted by the lab for analysis.

Your lab may still be willing to perform the analysis on samples not meeting the established sample acceptance criteria, but a certified lab will alert you to the fact that your results may be rejected by a regulatory body such as the EPA or your state’s Department of Environmental Services. When you are testing samples for regulatory or compliance purposes and they fail the acceptance criteria, you will be advised to resample.

Sample acceptance criteria are dictated by industry standards as well as regulatory procedures. Therefore, before you begin collecting your samples, it is always a good idea to check with your lab about sampling requirements for the analysis you need.

Here are six of the most common reasons that environmental laboratory customers might be asked to resample:

Expired or Nearly Expired Holding Time

A simple way to understand the concept of “holding time” for lab samples is to think of it as you would an expiration date on a perishable food item you purchased at the grocery store. The holding time is calculated from the time the sample was collected to the time it is prepared for analysis at the lab. If the allotted time has expired, and your lab data is needed for compliance or regulatory purposes, you will be asked by the lab personnel to collect additional samples.

Holding times vary widely by test, and can range from a few hours, to days, weeks, and in some cases, months. Holding time requirements are dictated by industry-specific protocols, and are established according to the analyte, analysis method, and other factors, in order to minimize changes to the material’s properties that were present at collection and to ensure accuracy of the results.

Holding times play a big role in sample acceptance. When accepting your samples for analysis, the lab personnel must calculate whether they have the capacity, time, and analysts available to perform the requested test before the sample expires. Like triage in an emergency room, tests with short holding times, such as Bacteria and Biological Oxygen Demand (BOD), are always prioritized by the lab. But even if your sample still has 48 hours until expiration, if you drop it at the lab at 4pm on a Friday afternoon and they are closed on weekends, or they are extremely busy with samples dropped off and set to expire ahead of yours, it is quite possible that your project will be rejected. This is another good reason to communicate your sampling plan and timeline with the lab ahead of time.

Samples Not Kept at Required Temperature

In addition to getting your samples to the lab as soon as possible, it is important to note that most environmental samples must be chilled with ice immediately after collection and kept cold until analysis.

Environmental samples should be received at the lab at 6 degrees C or below (but not frozen), preferably in a cooler with ice. The lab login staff will check the temperature of your samples upon receipt.

Samplers should also pay particular attention to outdoor temperatures on the day of sampling. For example, samples collected on extremely cold days are at risk of freezing, as well as broken glass vials due to expanding volume, both of which will render your sample(s) unusable. Conversely, on very hot days, you should travel with extra ice and be sure to monitor your samples closely to ensure they do not become too warm.

Lab customers will often ask why the temperature of the sample is so important. In order to accurately determine the results, samples must arrive at the lab with the same chemical composition that existed when the containers were filled. Chilling the sample slows any chemical changes.

The chemical composition of your samples can change when they become too warm (or frozen), and while you may still request the analysis in these cases, the lab is required to include the temperature non-conformance on the lab report. Therefore, the lab results may be invalid for compliance reporting or regulatory purposes. These sample integrity steps help ensure that your test results are accurate.

Incorrect or Incomplete CoC

The Chain of Custody (CoC) is a legal document, required by law upon relinquishing your sample to the lab. An incomplete or incorrect CoC may not result in sample rejection, but it may result in project delays, and in rare cases, cause samples to expire.

Since the CoC is a legally binding document, laboratory certification requirements are very strict about what a lab can or cannot accept on the CoC form. CoCs reflect the literal chain of custody of the samples, identifying each individual who accepts possession of the samples, the date and time of possession, from collection to lab analysis. The CoC also documents the sample IDs, collection information, analytical parameters requested and any other information the lab may need at sample receipt. CoCs document who should receive the final report and invoice, if the project requires an Electronic Data Deliverable (EDD), and special requests such as expedited turnaround time.

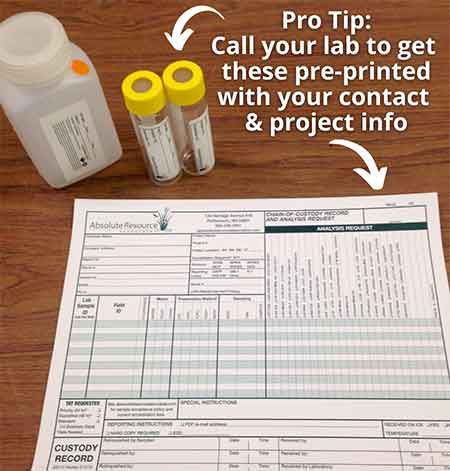

It is helpful and wise to fill out some of the general information on your CoC before you begin sampling, such as contact information, project name, and reporting limit information. As you collect your samples, it is best to write the sample ID number, the collection date and time directly on the sample containers. You must also record this same information on the CoC; the IDs, dates and times need to match between containers and the CoC form. Pro tip: contact your lab to see if they offer pre-printed CoCs and bottle labels to make this process much easier.

Always double check to make sure you are marking off the correct analyses and providing all necessary instructions on your CoC form. Your lab should catch any CoC issues at sample receipt, but if not, your project may experience unexpected delays, especially if the CoC errors / omissions have caused your samples to expire.

The Most Common CoC Errors We See at Our Lab:

- Discrepancies between information written on container labels & what’s recorded on CoC.

- Dates & times of sample collection not recorded.

- The CoC is not signed as relinquished by customer.

- The turnaround time or date needed isn’t noted on CoC.

- Samples received were not listed on CoC.

Incorrect Container Size

Some lab customers will unknowingly grab a water or soil sample without talking to the lab first, and labs have reported samples being dropped off in food storage containers, resealable plastic bags, and even recycled juice containers. What these customers don’t realize is that most environmental samples have very specific requirements in terms of what type of container is used for the sample.

For example, when testing for total metals in water, you must use a container pre-preserved with nitric acid, while the test for EPH requires an amber glass bottle and hydrochloric acid preservative, and the test for bacteria requires a specific sterile plastic bottle. The bottle types are specifically assigned to protect the chemical composition of your samples during transit and avoid any cross-contamination issues.

For larger sampling projects, timelines and logistics can be quite complicated, and will play a big role in bottle / container preparation. Many labs will combine tests when possible, to reduce bottle ware and collection time in the field. Additionally, there may be slight variations from lab to lab, so in most cases you will want to provide your sampling plan to your lab, and use the bottles they provide, to avoid discrepancies or misunderstandings.

Air Bubbles in Sample Container

For most analyses, a small air space in your container is inconsequential, but your lab may ask you to resample when air is observed in the sample for certain tests. For volatile organic analysis, there must be zero head space in the vials, as to ensure the integrity of your sample and accuracy of the analysis. It is a common and difficult problem for samples requiring the use of the 40mL vial, and customers often ask why a tiny bit of air is such a big problem.

When air bubbles are visible, there is a very good chance that volatile analytes present in the sample will off-gas into the air space, therefore reducing the amount of that analyte in the water sample. If that water were to then be analyzed, it would not be a true representation of the VOCs present at the sampling site. A good trick to check for air in your sample is to seal the cap, turn it upside down, and very gently bump the hand holding the container against something firm; if you see bubbles in the container, remove the cap and try again to achieve “zero headspace.”

Not Enough Material/Volume in the Container

As with most scientific studies, the sample size has a direct impact on the accuracy of the result. When testing your environmental samples, your lab will not only need enough of the material for the standard analysis, but also an extra amount for quality control, re-analysis if necessary, and sometimes additional tests on the same material.

You also want to ensure that the sample amount is sufficient to accurately represent what contaminants may be present at your sampling site. Too little sample often results in the reporting limit being higher, which can often be above the EPA or project limit that the customer is trying to achieve.

Lab customers are not expected to know, or guess, how much of a sample should be collected; those requirements have been established by the EPA and industry protocol. Your certified lab will be able to provide you with guidance on sample size requirements, as well as sampling procedures, bottle type, holding time, and all of the other issues mentioned here.

You can view a chart with bottle type requirements and holding times for many environmental analyses in the “forms” section of our website.

Conclusion

You put a lot of work into your environmental projects, so don’t let hiccups at the lab cause any delays or frustration. Laboratories are highly regulated and have many specific requirements that samplers and project managers need to be aware of. Here are a few final sampling tips to ensure you avoid any headaches on your next project:

- Whenever possible, share your sampling plan with your laboratory. A Certified Environmental Lab is well versed on sampling requirements and can help you avoid errors in the field. When this information is provided ahead of time, your lab may also be able to provide customized Chain of Custody Forms (CoCs), pre-printed labels with your Sample IDs and project information, and provide you with the appropriate bottles.

- Consider arranging for a courier to meet you at the site, your office, or a half way meeting spot on your sampling date. This will help alleviate any short holding time concerns and ensure that your samples get to the laboratory as soon as possible. Many labs offer free courier service to your site or office; it can’t hurt to ask!

- Also, remember to start cooling the samples on ice immediately, even if you are expecting courier service imminently. Most lab couriers travel with extra coolers and ice, but when the samples are still in your custody, they must be put on ice immediately, and kept cool until the sample and CoC transfer occurs.

When it comes time to submit your soil, water, and other environmental matrices for lab analysis, follow the steps listed here so that sample collection, transfer, submittal, and final reporting of laboratory data is a seamless part of your project. Good luck and happy sampling!

© Absolute Resource Associates